Hello All,

Today, we announced our entry into the global water and wastewater markets with our first motor product using our patented thermal dispersion technology: COOL TECHNOLOGIES’ DRY PIT SUBMERSIBLE MOTOR.

Way back in 1957, my father led a team of design engineers at Reliance Electric that designed the first Tandem Seal Submersible motors. Reliance worked with companies such as Crane Pumps, Paco Pumps and ESSCO Pumps and brought 3 diameters (motor sizes) to the water and wastewater markets: 140TY, 180TY and 210TY.

The product line expanded, as submersible motors became more accepted, to the 360TY diameter or frame while output increased up to 150 hp. That product is still around today and manufactured by ABB under the name Baldor/Reliance Electric Submersible motors.

In the early 1990’s, my co-founding partner, Mark Hodowanec, and I were at Reliance Electric. We developed and brought to market many new submersible motor designs up to 2000 hp. They included low voltage and medium voltage, submersible gear motors. Then, jointly with Yeomans Chicago Pump (now Grundfos), we created the Closed Loop Cooled (CLC) self-contained system.

We took on the industry leaders, Xylem Flygt, KSB, and Ebara and they adopted our technology.

I mention the CLC because Xylem Flygt recently brought to market their version of the CLC. Great technology, for the 1990’s, but it still has obvious thermal limitations. Mark and I know, we invented it with YCP.

Today, in the $100B+ global water and waste water markets, the industry still uses the following methods to cool motors:

1. Oversize the frame: This involves increasing the diameter and adding active material in order to meet the thermal standard set forth by UL, CSA and FM for skin surface temperature and as well as total rise by resistance internal of the motor and insulation systems.

2. Water Jacket: This is a metal casing which uses the effluent (the pumped medium), to cool the motor. It’s thermally limited and involves a lot of filtering, overdesign of pump impellers and wiping vanes. Plus, it’s very expensive to produce due to the cost of water jackets. If you design correctly, you have to mill flow patterns in the frame and jacket to guide the liquid to the motor hot spots in order to cool them.

We will post in the weeks to come, our technology vs. ABB (Baldor/Reliance Electric) in a dry pit to dry pit comparison (They currently oversize the frame or use water jackets). These are EXPENSIVE solutions for pump OEM’s.

3. Air over Blower: Based on the drives the industry used when vector AC motors came out, this enclosure is called TEBC: Totally Enclosed Blower Cooled. Again, it’s high maintenance and the blower has to shut off when the motor becomes submerged, so the blower has to be a submersible as well. That’s EXPENSIVE, adds to the complexity and is not a great solution from a service and sustainability standpoint.

4. Oil Cooled: FE Myers and others under the Pentair Pump Company use this technology today. You immerse both stator and rotor of the motor in oil and operate, but, just like in your car, heat breaks down the viscosity of the oil and so it’s effectiveness is limited. Plus, if it leaks, you just dumped oil into the sewer or clean water application you are pumping!

5. CLC: When we developed this technology, it was a way to get rid of 1, 2 and 3 above. It worked, but we had to use a water/glycol solution. Plus, the motor is cored with channels to control the flow up and down the frame so, it’s expensive to produce. It’s also heavy because you need a certain wall thickness to ensure you meet industry standards. And it’s expensive to cast due to the many core boxes. The frame, the drive end and the opposite drive end brackets must be cored.

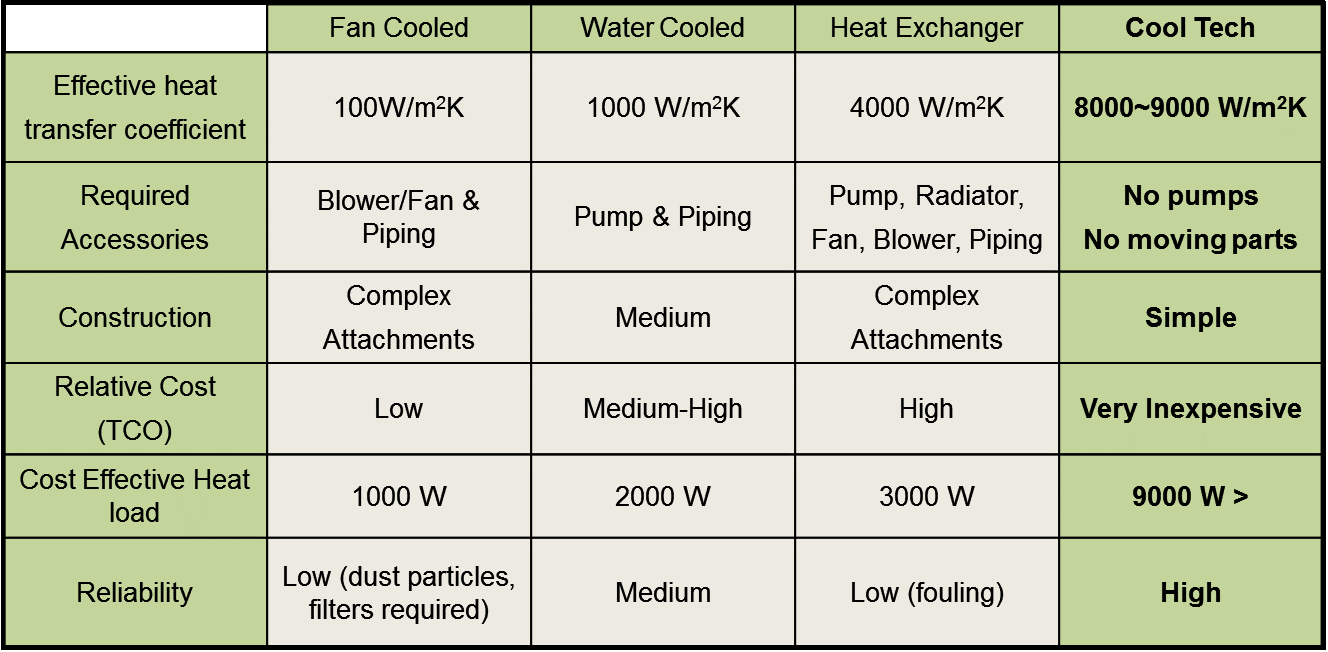

Cool Technologies needs none of the above. Our PASSIVE, patented, TEHPC™ (we own this trade mark) or Totally Enclosed Heat Piped Cooled, allows for maximum power density per diameter. That will yield designs which weigh 30% to 50% less and need no outside sources of cooling.

Let me repeat. With our thermal technology, ALL OF THE ABOVE is not needed.

With our manufacturing partners and pump OEM partner or partners, this product will come to market. The first diameter has been tooled in Orville, Ohio and the assembly will occur in Brownsville, Texas. Our motor supply partner is none other than NIDEC, the leader in vertical solid and hollow shaft motor technology. After all, a submersible motor is a VSS (Vertical Solid Shaft) motor, but it is also beyond VSS, it is VSS-SUB (SUB= Submersible).

Dry pit submersible applications out number submersible applications by 3:1. Now the end users: municipalities, lift stations, process plants, parks etc. will have a cooling solution that is smaller, lighter weight, superior technology which costs less than what’s incorporated in products on the market today.

We have brought in an industry product line manager to oversee the launch of the product. This person has more than 35 years in the motor industry and immense experience in NPI’s (new product introductions). That’s important because, with new product launches, you want a business leader who knows, design, manufacturing, marketing, sales, quality, the processes as well as the balance and checks system to ensure you do it once, do it right, and never look back.

As we head out of 2015 and into 2016, our company is positioned to drive revenue. In my next blog, coming very soon, I will expand on the timing of this product in 2016 as well as have our business leader make comments on this product and give you the opportunity to ask questions.

Also, we have a registration area just to the right of the blog. Please take time to register, so that you will be notified of blog updates and news we release.

Last, I had some great questions come in that I will post responses to in the next few days on our MG and on the company.

Stay tuned.

Best to you all,

Tim Hassett

Chairman & CEO